#ASME Y14.5 1994 THREAD STANDARDS SOFTWARE#

The geometry and topology of parts modeled in CAD software can be checked for defects.

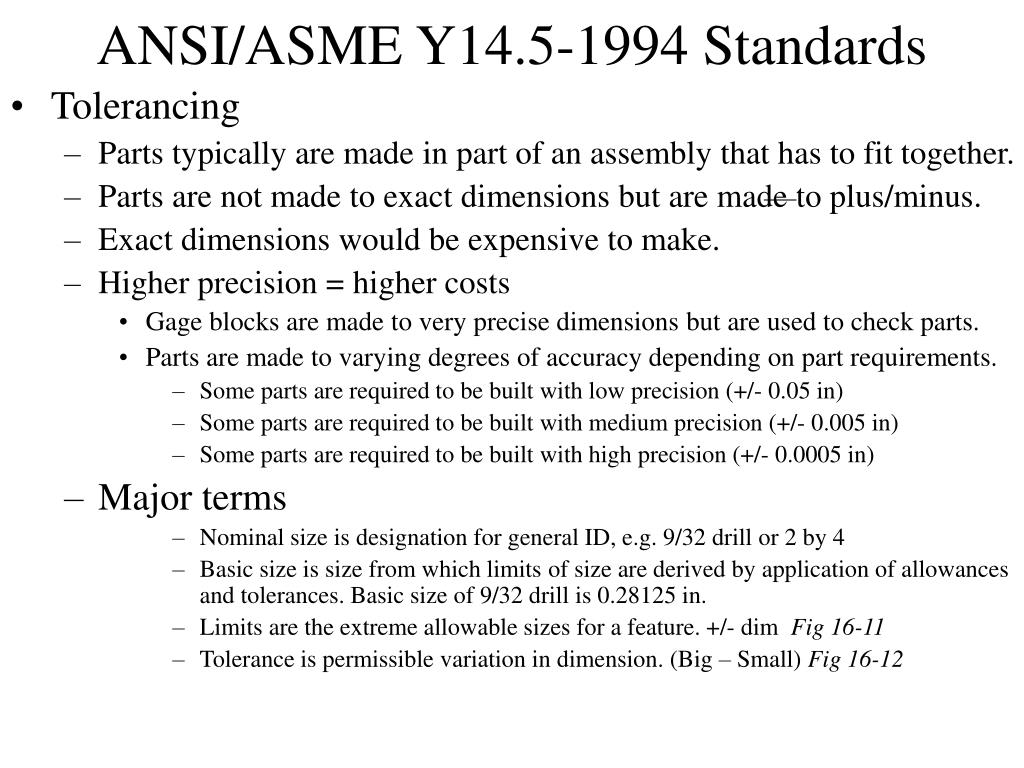

The testing project results can be used as a basis for future testing, methods, and standards to evaluate defects in GD&T applied to part features. The testing methodology, test results, and data analysis demonstrate how well the CAD system GD&T implementations perform. Errors with semantic representation and graphical presentation of the GD&T were collected and analyzed. Representative part geometry with GD&T applied to features was modeled in four of the major CAD systems. To improve that situation, the National Institute of Standards and Technology (NIST) has developed a system to test implementations of GD&T in CAD software. However, there has never been any rigorous public-domain testing of CAD software GD&T implementations. Of course, CAD software vendors do their own internal testing of those capabilities and users evaluate CAD software so that it satisfies their CAD modeling requirements. However, it is not well characterized how CAD software implements capabilities for a designer to apply GD&T to a part. As the accuracy requirements in assemblies became tighter, designers had to consider other critical dimensions and allocate tolerances to them in order to ensure the assembly's functionality.Applying geometric and dimensional tolerances (GD&T) to part features in computer-aided design (CAD) software is essential so that the part will function properly and to guide downstream manufacturing and inspection processes. During the inspection process, a part is rejected if a dimension fell outside the specified range. Fits of mating features included clearances, location fits, and interference fits, with various sub-grades in each category assigned a tolerance value depending on the nominal size of the mating features. Tolerances were specified to ensure the proper function of mating features. The notion of associating a lower and an upper limit, referred to as tolerances, with each dimen sion was introduced.

Machine designers realized very early that manufacturing processes do not produce the nominal dimensions of designed parts. The field of tolerancing design is successfully making the transition to maturity where deeper insights and sound theories are being developed to offer explanations, and reliable implementations are introduced to provide solutions. The research efforts and innovations in the field of tolerancing design, the development of supporting tools, techniques and algorithms, and the significant advances in computing software and hardware all have contributed to its recognition as a viable area of serious scholarly contributions. The importance of proper geometric dimensioning and tolerancing as a means of expressing the designer's functional intent and controlling the inevitable geometric and dimensional variations of mechanical parts and assemblies, is becoming well recognized.

0 kommentar(er)

0 kommentar(er)